Pipe crimping tools are essential instruments in the plumbing and HVAC industries, designed to securely fasten fittings onto pipes using a crimping technique. These tools come in various types tailored for different materials such as PEX (cross-linked polyethylene) and copper pipes, each offering unique advantages depending on the application requirements.

Types of Pipe Crimping Tools

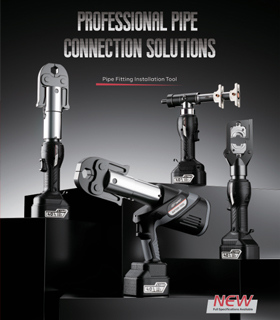

Pipe crimping tools are broadly categorized into manual and hydraulic types. Manual crimp tools are operated by hand and are suitable for smaller-scale projects or instances where portability and ease of use are prioritized. They exert sufficient force to create a secure crimp connection without requiring external power sources. Hydraulic crimp tools, on the other hand, utilize hydraulic pressure to achieve higher force outputs, making them ideal for larger diameter pipes or high-volume installations where consistent crimp quality is essential.

Applications in Plumbing and HVAC

In plumbing applications, PEX crimp tools are extensively used for joining PEX pipes and fittings. PEX piping systems are favored for their flexibility, resistance to scale and chlorine, and ease of installation compared to traditional copper pipes. The PEX crimping tool compresses copper or stainless-steel crimp rings around the pipe and fitting, creating a reliable seal that withstands the pressures and temperatures commonly encountered in plumbing systems.

Copper pipe crimping tools, on the other hand, are employed in both plumbing and HVAC installations where copper piping is prevalent. These tools ensure a secure connection between copper pipes and fittings, crucial for maintaining plumbing integrity and preventing leaks over the long term.

Design and Features

Modern pipe crimping tools feature ergonomic designs that enhance user comfort and reduce fatigue during prolonged use. They are engineered to deliver precise crimps consistently, minimizing the risk of improper fittings or leaks. Adjustable crimping jaws accommodate various pipe sizes, offering versatility across different projects and pipe dimensions. Some advanced models may include calibration gauges or ratcheting mechanisms to ensure the crimp rings are properly seated.

Advantages Over Other Connection Methods

Pipe crimping tools offer several advantages over traditional connection methods such as soldering or gluing. They do not require the use of open flames (as with soldering) or harsh chemicals (as with gluing), making them safer and more environmentally friendly. Crimped connections are also quicker to install and require minimal skill or training, making them accessible to a wider range of professionals and DIY enthusiasts alike.

Maintenance and Safety Considerations

To maintain good performance and safety, regular maintenance of pipe crimping tools is essential. This includes inspecting the tool for wear or damage, lubricating moving parts as necessary, and storing the tool in a clean, dry environment when not in use. Operators should always follow manufacturer guidelines and wear appropriate PPE, including safety glasses and gloves, to prevent injury during operation.

Industry Trends and Innovations

As the plumbing and HVAC industries evolve, so do pipe crimping tools. Manufacturers are increasingly integrating smart technologies such as digital pressure sensors and programmable settings that enhance accuracy and efficiency. Additionally, advancements in materials used for crimp rings and fittings contribute to improved performance and longevity of crimped connections, meeting the growing demands of modern construction practices.

Pipe crimping tools play a crucial role in modern plumbing and HVAC systems, offering efficient and reliable methods for securing pipe fittings without the need for soldering or gluing. Whether for PEX or copper piping, these tools provide versatility, ease of use, and consistent performance across various applications.

English

English Español

Español русский

русский Français

Français Deutsch

Deutsch Português

Português